|

posted by: Sirarcalot

No problem, Rusted. I can't believe how

this vise story is keeping my attention. I'm telling all of my friends at

work about this soap opera. And, of course none of them are interested.

They just don't get it. Some people just don't appreciate a good story.

posted by

Cutter 05-02-2004 posted by

Cutter 05-02-2004

Clear the bridge. Just kidding, that

was too much even for me.

Well guys,

I've been reading all your comments and thinking them over for an hour or

two. I'll try to address them in one or two posts instead of one per post.

Looks like we've got 5, maybe 6 types of "treatments" on the table:

1. heat

2. diesel

3. Kroil with or without zerks or PB Blaster

4. impact - tapping, hammering, sledging, beating it to death

5. pressure or a combination of all or several (such as heated diesel)

6. and Stinger's suggestion of drilling out the key, which I ain't gonna

attempt to do because I am not equipped to drill it cleanly without

ruining the slots it runs in. While I'm here - Stinger, the the key &

keyway are not visible from the front through the main casting which gives

me the impression that the key is fixed to the main casting. A look at the

next to last picture (of the butt end of the vise) bears that out. Notice

that the major portion of the slot is in the slide & the slot in the

casting is just deep enough to serve as a positioning groove for the key.

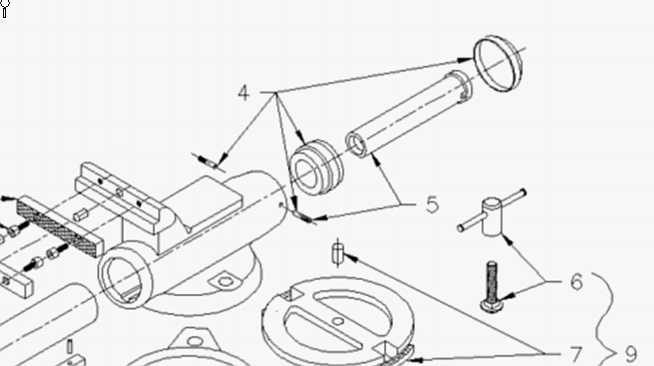

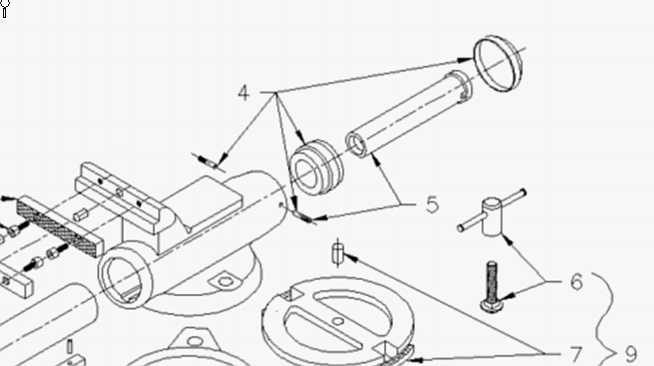

I also have an exploded view of a similar, later model Wilton that

indicates the same thing. This is a bit curious because the baby 903

Wilton that I posted does have the key attached to the slide. Go figure.

At any rate, drilling it is simply not a practical thing for me to do. I

will show the exploded view below. Look at the complete circle at the

front of the base.

I tend to favor diesel right now because of time considerations. I will be

too busy during the next several days to screw with it very much and then

be gone for a few days. It will be the weekend of May 15 & 16 before I can

do any serious tinkering anyway. And I know where to get diesel as

compared to probably having to order Kroil or at least run around town

trying to buy some locally.

Furthermore, leaving it soaking in diesel requires no babysitting and

prevents additional rusting while I'm out of pocket.

By the way, Sirarcalot, I have a spray can of PB Blaster, bought it at

NAPA, tried it for a few days but I really think its gonna take a minimum

of a gallon of any kind of solvent; I could plug the front end, set it on

its nose and fill the inside with Kroil or PB and just keep topping it off

every day. But diesel is a lot cheaper and so much more accessible. If I

do get into that, I do know that Kroil can be ordered in gallon sizes for

about $22 plus shipping, I don't know about PB. And I do like Jim's

suggestion about the grease zerks.

As for as heating it goes, building a bonfire in my backyard sounds like

more fun that it would really be, I'm afraid. I just hate being handcuffed

& riding in a copcar - too much novelty. It wasn't even fun the first

time. I'd rather use the old cookstove idea & even that would be a pain in

the butt to arrange. However, I can do it if I have to. But not until

later in the month.

Hammering doesn't seem to get any results at all. I think that's because

we're dealing with 16 - 18 inches of a massive, rusted, tight fitting tube

& sleeve here. And it dents easily; it was already scarred up pretty badly

when I found it. Adding to it seems pretty pointless to me.

I think my homemade press will be called back into duty after a period of

soaking and I will need a new backing disc to even do that. I guess I need

to find some 1/2 " plate to use for that because 1/4 inch just didn't hold

up last weekend.

So from where I sit right now, the diesel soak looks like the most

practical idea. A note about the cost of this kind of thing: with a few

exceptions, keeping the cost way down just adds to the fun of a project

like this. The idea of spending $200 - $300 in either materials or outside

labor just defeats the concept as far as I am concerned. That's why I

don't really enjoy those lame tv shows like American Chopper or American

Hotrod very much - they don't even have to consider the expense of the

custom parts or paint jobs. Where's the challenge & fun in that? Most of

us have to give up something else when we do that, if we can afford to do

it at all. So there again, diesel fits the bill mo' better. Now that

pretty much defies what I did with that old Delta vertical bandsaw that I

restored last fall & posted to the Hobart site, but that was one of those

exceptions for me. And it is proving itself to be darned well worth the

$300 or $400 I invested in it. The difference in the 2 projects is that

there is really no other way to get a 1945 model metal cutting bandsaw

unless you spend about 3 times as much for one somebody else has already

refurbished. I already have other vises I can get by with. And when I do

get this cranky old thing back into a useable state, it will be an real

joy to use just because I poured so much care into it and all of you

fellows were witnesses and collaborators to the deal.

Maybe that's why you keep coming back to see what's going on ; I have

really wondered about that myself. At the present time there are 6515 page

views of this thread & that just amazes me. I guess it strokes my ego but

nevertheless, it is deeply gratifying to have somehow kept your sustained

interest for 2 months now and I really do thank you for it. Someday, it

will suddenly be done. I hope.

posted by: fla jim

Cutter:

Diesel might work. I still would drill and tap some Zerks into the body,

and use a grease gun filled with Diesel fuel to inject diesel into the

body. I'd still ;eave it soak about a month filling it every day or so

before I attempted to seperate it again.

posted by: stingers

All the skin lotion, Diesel fuel,

Liquid Wrench, etc. in a bath applied to the outside of the vise body

isn't going to soak in. The only access to the bore of the vise is that

thin parting line between the vise body, key and barrel. If-if any

penetrate can get down that crack-gap it's going to take a miracle. You

can plug the hole in the barrel and fill the end of the vise with whatever

liquid of choice-that should be enough. The same goes for the other end as

far as that thin line of access. So you shouldn't need a gallon of

what-ever.

Even if anything penetrates that bore, the grip between the two moving (?)

parts because of the amount of surface involved is going to be difficult

to overcome. Getting the two contacting surfaces to separate a tad should

help.

But I'm with you. I'm stubborn too. You might heat the vise in that stove

and then use a CO2 fire extinguisher and shoot the hole with CO2 to see if

it would shrink the tube to loosen it.

posted by:

Mike W

Ok, I have an idea. Do you know what an

oxygen lance is for cutting steel? It is a piece of pipe hooked to the oxy

regulator. A torch is used to start the cut and then the lance is brought

into play.

Make one on a smaller scale and you should be able to cut out the key

stock for it's entire length.

posted by: SDean

quote:

--------------------------------------------------------------------------------

Do you know what an oxygen lance is for cutting steel?

--------------------------------------------------------------------------------

Jeez Mike, He's trying to SAVE this vise.

posted by

Cutter 05-02-2004 posted by

Cutter 05-02-2004

LOLOL! My thought exactly.

Some of these guys appear to be trying to get me to act out their

fantasies or something.

I know, I asked for suggestions so keep them coming. So far I don't have a

death wish

so I think it's ok for you to keep trying.

posted by: Franz

Obviously Mike has never had an up

close & personal relationship with an Oxygen Lance!!

Cutter, given that I've put 48000# of push on a rusted up Reese receiver

to move it, much to the constirnation of the press owner, I've come to be

a great believer in patience and heat, along with air hammers. There is a

lot to be said for air hammers, along with appropriate striking surfaces

machined to fit.

I generally try to hang onto the thought it wasn't working when I got my

hands on it, and all I really gotta do is NOT break it. You sure as hell

ain't gonna hurt it by soaking it in diesel for a month or 2.

posted by: stingers

Cutter;

I was looking at the photo in post #532. Do I see a hole pitted through

the forging bore into the keyway? Just wondering. If I was trying to drive

the movable jaw barrel, I would make a counter-bored steel cup for the

jack post to fit into that was stepped down to slightly smaller than the

barrel with a pilot turned on the end opposite the jack pocket that

located/centered the cup. Cut a slot to clear the key. Reading your

thoughts- the key is pinned so it shouldn't move?

I found a 50 ton bottle jack that works horizontally so maybe you can find

a loaner. Then you will have to find something to handle that much

pressure to push against. Heavier chain or heavy steel bars and cross bars

all bolted together. Chain or strap both the jack and the vise down to the

I beam. I'd cover it like you did before and sand bag every thing but the

jack handle.

I know the results of squeezing a solid bar of aluminum (stop block) out

of a 200 ton press.

posted by:

Mike W

If you can blow out a broken off bolt

in a cylinder head with a torch.....I have never tried it, then why can

you not blow out a steel key stock in a cast iron vise?

I don't think a jack is going to work.

posted by: Franz

Because you're generally blowing a

steel bolt out of a cast iron cylinder head. Steel burns with O/A, Cast

Iron doesn't.

Now, if we're going to go to the exotic, it would be relatively easy to

remove the key with a wire EDM, but I don't think Cutter has one of those

machines in his back yard.

posted by: boilerman

i vote for a 1 month diesel bath

posted by: Banzaitoyota

how about taking it to someone with an

ultasonic cleanr?

posted by: stingers

quote:

--------------------------------------------------------------------------------

Originally posted by Franz

Now, if we're going to go to the exotic, it would be relatively easy to

remove the key with a wire EDM, but I don't think Cutter has one of those

machines in his back yard.

--------------------------------------------------------------------------------

Yep, a wire EDM would sure do the job, but the catch is you need a hole

drilled the length of the key to feed the wire through and Cutter isn't

drilling any holes-yet.  I

don't know how thick (length of the vise key) an EDM's spools will open up

for and the movable jaw is in the way anyway. There probably are some EDM

machines than could hack it if it wasn't for the front end of the vise.

Grumble-grumble. I

don't know how thick (length of the vise key) an EDM's spools will open up

for and the movable jaw is in the way anyway. There probably are some EDM

machines than could hack it if it wasn't for the front end of the vise.

Grumble-grumble.

posted by: Franz

OK, if it wasn't for IF, cowshit would

be buttermilk, and farmers would be rich.

All that phylosophysin aside, maybe Cutter can build something like this

in his spare time and remove the key.

http://pico-systems.com/edm.html

Then again, I ain't absolutely sure the key is the problem, so after

Cutter removed the key we could still have a frozen vise.

|

posted by

Cutter 05-02-2004

posted by

Cutter 05-02-2004