|

08-24-2004

posted by

Cutter

posted by

Cutter

New Shop Building

It's a funny thing how life can suddenly shift gears and accelerate. Last

Thursday I made my appearance before the zoning board to request a

variance in the setback requirements for my shop building, expecting to be

stuck there most of the day. In less than an hour I left with a verbal

"ok" on the deal & went back to work. Saturday I got the letter with

official approval in the mail. I spent Saturday & Sunday afternoon making

phone calls mainly hoping to get a favorable referral to a concrete

contractor that I could maybe line up to pour my slab sometime in the near

future, expecting this process to take a few days. As it happened my old

friend Harold had stumbled across a man who poured a drive & several

smaller pieces for him a month or so ago & he had high praise for him. I

left a message on the guy's machine Sunday afternoon & he was here at 4pm.

The result is that Pete & crew start this afternoon. I spent Monday

afternoon getting the permit & picking up the bolt pattern from the

building supplier 15 miles away, along with the anchor bolts and I managed

to scrounge enough chain link fence & t-posts to build a temporary dog run

for Dottie & Jake. Somehow, all of this was more exhausting than work.

Maybe it was the sticker shock.

If you built your building last year, congratulate yourself. If you

haven't priced a building this year, take a deep breath. Steel prices are

up; perhaps you've heard about that. This is a standard kit building from

Mueller, 24 feet wide, 30 feet long, 10 foot side walls. The basic package

engineered for 120 mph wind load, 20lbs per sqft snow load: $5795. Add

insulation, 2 walk doors and some extra material for re-working the

overhead door opening, colored roof, add deadbolts to the doors, plus tax

& free delivery to my slab: $8235.18. The slab is costing about $2400,

then there will be the 24 ft x 12 ft wide drive to the side street for

another $1400.

But I do have some good news: I saved a bunch of money on my car insurance

yesterday by switching to monthly drafts.

__________________

cutter

08-24-2004

posted by Wyoming

Cutter, Congratulations! A word of advice...make sure there is a grade

change between the shop floor and the drive outside or you'll be having

rain water to clean up after every storm. Throw in a ceiling so you can

add insulation up there as well...makes the shop much more liveable in

both the summer and winter. Last bit of advice...if you use vises, anvils

and such, sink as many female end sections of drill casing to grade in the

floor and it will be a snap moving vises, anvils and such mounted on male

sections of drill casing around as needed. Good luck on the build and hope

to hear you get a lot of use from the shop.

08-24-2004

posted by big rig guy

Very good Cutter, I hope to see lots of pics during construction. What

about drains in the shop floor ??????

__________________

There's a method to the madness, disturb the method and the madness

begins.

08-24-2004

posted by

Cutter

posted by

Cutter

Quote:Originally Posted by Wyoming

Last bit of advice...if you use vises, anvils and such, sink as many

female end sections of drill casing to grade in the floor

!!!! I don't know if we have a drill casing store anymore, WY. Can you

overnight me a couple of couplings?

__________________

cutter

08-24-2004

posted by Franz

Cutter, I been noticing even the ads on Paul Harvey for steel buildings

ain't playin any more, and when I swung by the supplier a couple weeks

back to get some steel for the awning I built over my garage wood pile, I

got a bit concerned when the one kid came runnin with the oxygen bottle.

3 foot coverage steel is 2 bucks a foot minimum, with delivery of 2 to 6

weeks depending on color.

08-24-2004

posted by

Cutter

posted by

Cutter

Well the hell of it is, I don't see any reason to expect the price to go

down any time soon unless the whole economy collapses under the weight of

the oil prices & then it wouldn't make any difference anyway. Even though

my timing is a year or two late, every month I put this off costs me

another $300 in rent for that danged old barn. I've already paid for

several of these little shops in the last 11 years & I'm sick of it. That

$3600 a year will recoup the cost of this project pretty quickly.

__________________

cutter

08-24-2004

posted by DDA52

Cutter

The slab $$ is awful cheap. Are you buying the materials?

Also, ditto Wyoming's comment on the grade drop at the doors. It doesn't

take much, 3/4" will do nicely. That is a favorite place for concrete

dudes to cut the corners on. They are a pain to finish, that's why. The

drop will make a major difference though. I'm sure you know what I'm

talking about, but if not, let me know and I'll shoot you a pic and

details. Since I am in the crete business, I hate it when people don't do

it right. I mean, that's what you're paying for isn't it???

__________________

Don

Grand High Poobah...(by appointment.)

08-24-2004

posted by

Cutter

posted by

Cutter

This is for Arcdawg

Get a grip now, Brian. Find a workboot or something to bite down on.

The build team so far includes Pete Chevez (concrete), John Hernandez

(little bit of plumbing) and Pablo Gomez (building erector).

I did not choose them because they are illegals; they aren't. I chose them

because of their work & reputations. In this part of the country,

Hispanics have carved themselves a solid place in the building and other

skilled trades and I am nearly always pleased to do business with them.

However, I have learned to not try to work alongside them in any

competitive way; they'll generally work you to death.

__________________

cutter

08-24-2004

posted by DDA52

Quote: Originally Posted by cutter

Get a grip now, Brian. Find a workboot or something to bite down on.

The build team so far includes Pete Chevez (concrete), John Hernandez

(little bit of plumbing) and Pablo Gomez (building erector).

I did not choose them because they are illegals; they aren't. I chose them

because of their work & reputations. In this part of the country,

Hispanics have carved themselves a solid place in the building and other

skilled trades and I am nearly always pleased to do business with them.

However, I have learned to not try to work alongside them in any

competitive way; they'll generally work you to death.

He'd die here. The population is 65% hispanic. In the concrete business, I

can only think of maybe a few dozen white guys in the whole city. ( pop

1.2 million)

__________________

Don

Grand High Poobah...(by appointment.)

08-24-2004

posted by

Cutter

posted by

Cutter

Quote: Originally Posted by DDA52

Cutter

The slab $$ is awful cheap. Are you buying the materials?

Also, ditto Wyoming's comment on the grade drop at the doors. It doesn't

take much, 3/4" will do nicely. That is a favorite place for concrete

dudes to cut the corners on. They are a pain to finish, that's why. The

drop will make a major difference though. I'm sure you know what I'm

talking about, but if not, let me know and I'll shoot you a pic and

details. Since I am in the crete business, I hate it when people don't do

it right. I mean, that's what you're paying for isn't it???

Yep, and thank you Don. Pete has already discussed the lip, called it a

rabbet & it took me a while to catch on. I have already lived in one house

that didn't have that litle detail - real PIA. I thought the price sounded

pretty cheap, too but that's turn key. I was kinda hoping some one would

comment.

Hmmm, I better get my butt outside & start getting ready for these guys to

show up. He'll be ragging me for being just another lazy white boy. Which

is pretty much the truth these days.

__________________

cutter

08-24-2004

posted by DDA52

Just out of curiosity, what is the slab design? Any interior beams?

(another favorite shortcut) Steel size?

__________________

Don

Grand High Poobah...(by appointment.)

08-24-2004

posted by DDA52

Oh yea, don't let them forget the siding pocket on the outside form. It

would be the same as leaving out the door pocket.

__________________

Don

Grand High Poobah...(by appointment.)

08-24-2004

posted by SlimJim

Cutter, I feel your pain brother. I am in the process of building a barn

and they are not giving away steel here either. Its is 60 x 80 and it

looks like i am going to end up with over 10 grand in it. That is with no

slab, no sides and barely any gables. Farming sucks. Maybe I should sell

all my cows. Naa, I cant do that with prices up like they are. I think I

will wait till they drop back down to record lows and then get out. Geesh,

I need a beer, now why did I quit drinkin Come to think of it, that barn

would make one hell of a shop with a little concrete and some walls.

08-24-2004

posted by

Cutter

posted by

Cutter

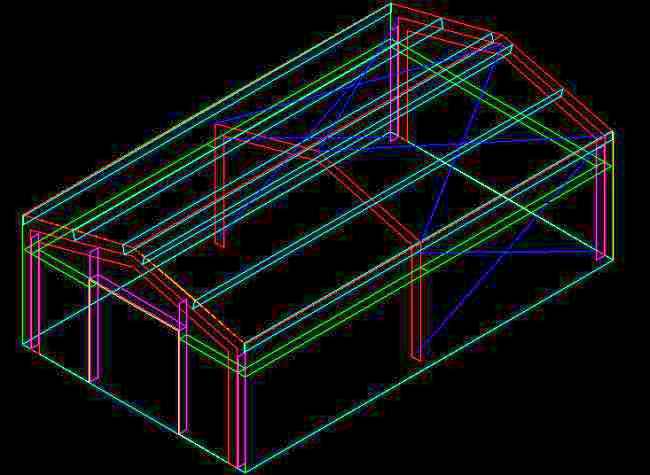

color sketch

This is a cad drawing (or something) that Mueller sent with an earlier

quote of a slightly larger much more expensive buildling. It was supposed

to provide support for a crane beam rated at 2000lbs, cost $3600 extra. I

decided I could do better than that. Not showing are a couple of walk

doors & some windows. The cross bracing is done with cables.

BTW, the slab work for today is recheduled to begin tomorrow, fine with

me; Pete & I have a common goal of completion this week.

__________________

cutter

08-24-2004

posted by

Cutter

posted by

Cutter

Quote: Originally Posted by big rig guy

Very good Cutter, I hope to see lots of pics during construction. What

about drains in the shop floor ??????

Big rig, I considered a drain but I really don't want to sacrifice the

flat surface for one. And I won't be washing any trucks. I intend to

install a 2 bucket laundry-type of tub just for parts washing & hand

scrubbing. And probably a urinal. They seem more & more useful to me these

days. I may relent & make it a commode, depending on what I can scrounge.

I've just always thought a shop should have a real urinal.

They kind of separate the delicate-type ladies from the real women, don't

you think? lol

__________________

cutter

08-24-2004

posted by rodburner

Hey Congrats on starting the new project cutter, show us pics of it in

production. Its a pain but once its finished its awesome.

__________________

Billy

08-24-2004

posted by 1911man

That's great Cutter sounds like it's really taking off. Just don't get

going so fast that you meet yourself coming and going!

08-24-2004

posted by 7018

Congrats cutter,bet u'll love having that shop i know i do like mine when

its clean

08-24-2004

posted by Paychk

Dude

All I can say is I'm jealous !

Too cool!

__________________

Ory-gun Boy!

08-24-2004

posted by Jim314

Good deal Cutter. I'm looking forward to seeing the construction pics!

08-24-2004

posted by Sberry

Yes, every shop needs a pisser.

I have a couple bathrooms too, but that setup and another sink on other

side keep a lot of traffic out of them. Here is a detail shot for the

engineer types.

This sink is in a handy spot, this was in the plans when I built, I had

one in the traffic zone in another building and it worked great.

08-24-2004

posted by arcdawg

CUTTER, i see that you have been busy while i have been chasing tail in

NYC

you know that i am not THAT narrow minded !!! i understand that us grinos

will be phased out like a commerdore 64

all smart *** remarks aside ... i have been running a crew of mexicallies

for a few days for my boss and those *******s are good !

good luck with the new shop......

(im pretty mellow even though i havent been snipped and clipped !)

dawg

08-24-2004

posted by Wyoming

Cutter, The wife and I have been gone all day on a Home Depot run down to

Casper. The drill casing goes for 10 cents a lb. scrap, but I think the

overnight air fee just might be the deal/back breaker. Now are you just

darned sure there isn't a casing store in your neighborhood? Seems like up

north of ya' a ways in Pampa I was swimming in the stuff back in '78 when

building a power plant outside of town for Celenese...you know the

one...it went boom a few years later. Gotta hand it to Pampa...it made

Lubbuck look like a garden paradise. As far as the floor drains go it

probably would have been a hard sell to your local building inspector.

Here in the land that government regulations nearly forgot you have to

install a sump pit instead of floor drains to get a sign-off. Again, enjoy

that shop. My wife talked me into having a retirement shop erected (40 x

60) twenty years early.

08-25-2004

posted by

Cutter

posted by

Cutter

Wyoming,

I was kidding about the "overnight" but my problem with the casing is

time. I called a guy tonight who drives a Mac "pick up" wagon for American

Iron & Metal, figuring he'd know if there was a scrap pile anywhere. He

came up blank. Best I can come up with would be some local pump company

but the slab should go down day after tomorrow or Friday. Finding time to

scrounge looks to be iffy. Standard pipe couplings in the 3 or 4 inch

range would be easier. Pampa is a whole different animal than Lubbock. I

used to work the Pampa area about one week a month 25 years ago when I

took a brief turn as a traveling salesman & I was in the Odessa oilpatch

enough that I kept a tiny apartment there for a couple of years. But we're

talking 180 miles north to Pampa, 160 south to Midland/Odessa. Not

something I can do on my coffee break. And Lubbock is almost entirely

agricultural, not much oil activity around here.

__________________

cutter

08-25-2004

posted by Wyoming

Cutter, If you like the idea of the well casing vise mounts in the floor

but don't have the time to run them down before the concrete arrives than

let me run another idea by you. Instead of planting the well casing to

grade install upside down empty gallon coffee/food cans. They can be

"pulled" when you have the casing handy. Only just a bit more work to run

a post hole digger down the opening, drill a hole or two into your slab to

run a short section of rebar into for flex support before welding it to

the casing and pour a bit of sakrete down the hole to make it all look

like it belongs there. Same goes for "blocking out" stanchions for your

overhead door protection if you think you might want the option later.

08-25-2004

posted by DDA52

Cutter

Leave outs could work if you don't get the casings. Maybe you could get

generic 2.5 or 3" threaded pipe couplers? They might work in a bind.

Styrofoam or sand bags/boxes make good leave outs also.

__________________

Don

Grand High Poobah...(by appointment.)

08-25-2004

posted by Sirarcalot

Congratulations on your shop. Cutter. I am also jealous. I wish I had the

room to expand. Until then, I guess my wife will have to do without a

garage. I hope you enjoy the heck out of that shop for all of us.

08-25-2004

posted by

Cutter

posted by

Cutter

Thanks, guys. I am indeed interested in the casing idea. Maybe I can

discuss this with Pete tomorrow once we get through a couple of other

hurdles, like getting that heavy little storage shed that is sitting where

the driveway is going to be. It has to go so the tractor & cement truck

can get in to do the slab. There are several little things like that

because I expected to spend the next week or two just trying to line up a

contractor to do the job. Pete really screwed me up by being available

now.

Sirarcalot - If I had a wife to deal with, there would be no shop in my

future either, I suspect. I don't really have enough room for this either;

I have a little patio that extends 11 feet out from my back door; there

will be 1 foot of open ground between it and the building. I am actually

going to have to cut the patio cover back 2 or 3 feet & gutter it. I will

also have to gutter the shop. But I figger that few wives would go along

with what I am doing. My dogs will adjust real quick & any women that may

come around here are either my kids or they are visitors & don't have a

vote.

By the way, I think its time you dropped a first name or something else

for us to call you because every time I try to type Sirarcalot I have to

edit it; I nearly always type "Sircarlot" the first time. It doesn't feel

right to shorten it to "Sir", Sirarc" makes me think of Star Trek & the

whole danged name feels too formal or something. Can we just call you Ted?

Or how about S'lot?

__________________

cutter

08-25-2004

posted by D York

Cutter...Congratulations on your shop. Wish I had the space for one that

size. Good luck on the build.

08-25-2004

posted by

Cutter

posted by

Cutter

Thanks, D. All you really have to do is be willing to part with your back

yard & wife. Well, that's not really quite honest; all you have to do is

get your wife to take everything you own except your tools & maybe your

truck so you can start all over. Then you can maybe buy yourself a little

bitty house and turn the back yard into a shop. See? It's not so hard.

__________________

cutter

08-25-2004

posted by Sberry

I like to not get in a yank before the pour and get everything I can under

the floor. Any electric, water, phone chases, drains, even air lines.

Hanging stuff in the ceilings is slow and saves running things over door

headers. I bite the bullet ant put another elect panel on the other side

just so I dont need to run a bunch of branch circuits every time I want to

add something.

08-25-2004

posted by D York

Cutter..What about having a few conduit runs crossing the slab in a few

locations so at a later date if you need elect. you could cut into and

pull wire as needed.

08-25-2004

posted by

Cutter

posted by

Cutter

Yeah, Sberry's got me to thinking.

__________________

cutter

08-25-2004

posted by Sirarcalot

Cutter. I guess I was just being shy at first, but since I seem to be

among friends. My name is Marcus. I think if I had it to do over again, I

would use a different screen name.

08-25-2004

posted by

Cutter

posted by

Cutter

Great, Marcus it is.

I was just having a little fun with you but Sirarcalot really is kinda

hard to type. Marcus is good.

__________________

cutter

08-25-2004

posted by realhfd

Cutter, looks like you got a great project going on there. Before we put

in our home we had a slab poured for a shop. Not as big as yours tho, only

24x28. After final on the home and other messes cleared up got started on

the shop. Was originally thinking wood construction but got metal instead.

Had my brother and another fella help me put it up. That was a fun job.

Have a water line out to the building just in case but haven't used it yet

except for a faucet at one of the outside corners. Was thinking of putting

in a john or something but have so many nice bushes an trees out back that

so far the space inside has been put to other uses. Anyway, have fun with

the project and enjoy the end result.

08-25-2004

posted by

Cutter

posted by

Cutter

Thanks, real - thanks to all of you for your good wishes and good will.

That's a good omen for the project. May as well start the ball rolling for

the contruction pictures; wanna see some hard Texas dirt?

Attached Images harddirt.jpg (40.7 KB, 374 views)

__________________

cutter

08-25-2004

posted by fatfrank

I know what you mean my the hard TX dirt. That's all we have around here.

You could have ran the soaker hose for those guy for a couple of days But

since you have a firm quote for the labor, let those guys earn their

money.

[Home] [1] [2] [3] [4] [5] [6] [7] [8] [9] [10] [11] [12]

|