|

09-30-2004

Sberry

The ground is a saftey circuit and not part of the working circuitry. Bare

is fine. Cutter should have 4 wires coming from his main entrance panel.

The neutral ansd the ground can be on the same bar in the main but it

needs seperate equipment bar in the garage with the bond strap or screw

removed in the panel. It also needs a ground rod at the garage attatched

to the equipment grouund bar. The N and the ground need to be seperate as

the N is a current carrying conductor in this system, if they are bonded

in the secondary panel the N currents will be carried via the ground wire

and apply some voltage to anything electrically grounded, you dont want

that. The ground wire is only to return a fault (short) back to the main

panel. The ground rod isnt for shorts, its to eleminate potential voltage

differences of the ground you are standing on and any equipment you may

come in contact with and for lighting strikes, best to shunt them to

ground instead of being carried back on your wiring system. Some what

simplistic explanation, but its the basics.

Here is a tidbit from Bob Keis,code guy. I never use the 3 wire system

anymore as in todays world adding a phone, metal gas like, puter cable or

steel water line would throw it out of compliance. 4 wire system is the

only way to go.

The panels in separate buildings are not really subpanels as far as code

is concerned. They are the service equipment for the structure. You can

have a subpanel from the service equipment in each building if you want.

Between buildings, section 250.32 applies and if there are metal

interconnections between buildings such as water piping, or air lines, or

any metal interconnection at all, then you must install an equipment

ground wire so if you have a 120/240 system, you would have four wires.

The neutral would be separated in each building and a grounding bar would

be installed, just like a subpanel. Then the code requires a grounding

electrode conductor (GEC) to a grounding electrode (usually a ground rod).

The GEC will be connected to the equipment ground bar at each building.

This is not to clear overcurrent devices, this is for two reasons. One is

lightning, the more important one is to put the equipment ground at the

same relative potential as the earth. This is for step potential or touch

potential voltages so that what you touch in the building is at the same

potential as what you are standing on. Now the tricky part. If you do not

have any interconnecting metal between buildings, the code allows you to

install three conductors between buildings. When you do this you bond the

neutral and ground the neutral just like a new service. Some inspectors

think that every panel in a separate building must be treated as a

subpanel, but this is not true. In past codes (1996 and older) these rule

were in section 250-24 and Exception 2 addressed the grounding bus.

09-30-2004

posted by

Cutter

posted by

Cutter

Thanks S; that provided lots of clarity. The final result was the same as

I had been told, but the reasoning behind it is what was lacking.

Now, I plan to run a second (3 wire) cable from the meter base through a

60 amp fuse box to the shop as a dedicated welding supply. It will be 2

hots & a ground because that is what the MM351 power cord is. Inside the

shop there will be a separate disconnect switch beneath the main panel for

the welder only.

How would you treat this circuit with respect to earth grounding?

__________________

cutter

09-30-2004

posted by Sberry

Its not a legal circuit. In the type of setting you are in you are allowed

only one multiwire circuit or service to a detatched building,,, that is

if you want it to be to code,, which isnt a bad idea. I would have wanted

to feed 100A, and you still could by replacing 2 wires.

10-01-2004

posted by SheepDog

I enthusiastically agree with Sberry. This is the time to upgrade the

service to your workshop. Feed the panel there with big enough conductors

to handle everything you think you'll ever need. Then feed ALL the shop

circuits from there. There's no reason not to follow code, and it will

save you hassle as well.

10-01-2004

posted by atucker

Cutter,

Since I am NOT an electrician, here's a thought you might consider in your

planning. You've got 100 amp service to the house and you'd like 200 amp

in the shop (I think?). Why not put in a new 200 amp (or greater) service

to the shop and then make the house a sub from the shop and remove the 100

amp service from the house? That way you'd still have just one service

(bill) and the majority of the power will be available in the shop (at the

source), where it will most likely be used and needed. If you don't want

to do it that way now, at least plan it and wire it that way.

IOW, put an entrance/service panel in the shop rated at whatever amps you

believe you will need. Use the "temporary" line from the house as the

source for now. Then at whatever time, you can put in the new bigger

service, move a few wires around, get rid of the meter on the house and

you'll be done. I realize that sounds kinda simplistic, but I can envision

your power demands overburdening your supply pretty quick.

Now the "code knowledgeable" folks can add their 2 cents .

Allen T.

10-01-2004

posted by fatfrank

I don't know if there are any codes against something like what Allen T

said, but its sounds logical to me.

Another thought for you cutter would be, just give me your 251 and I'll

bring you my HH175 and 100ft of 10g extension cord and you won't have to

run a new line for your welder. Just walk it in the house and plug it in

the dryer outlet. LOL

I'll even drive to meet you in Abeline for the exchange.

10-01-2004

posted by Sberry

More and more setups are going to that system of putting the main in the

garage, especially where the major appliances are gas in the house.

10-01-2004

posted by MangleWeld

Cutter when we bought this Farm years ago I did not look at the service,

when I did we found out it had a 60 amp maximum. I called our Rural

Electric Cooperative and they upgraded it to 200 amp at no charge, I'm not

so sure it would be free today. I thing you said you had checked on this

but if not try then on.

10-01-2004

posted by

Cutter

posted by

Cutter

There is no charge for a new 200 amp drop - already checked. And the field

rep who came out here to tell me what a 3 phase drop would entail also

suggested I run a 200 amp single phase for the shop & tie the house to it.

The kicker is that new service entrance equipment for the shop would cost

around $750 minimum. That's because my power company requires a new 200

amp meter base with a bypass, new 200 amp disconnect and of course, a new

200 amp breaker box before they will hook you up. The 2 inch pipe they

require for the weatherhead is $47 by itself. They also require the permit

signed off by a master electrician. I figure I would wind up spending

around $1000 - $1250 before I got the power back on & still have to do the

lights & outlets. Then I would have to deal with followup inspections. All

these service intrance requirements are so new that the powcom hasn't been

able to make up their minds whether they want the disconnect before the

meterbase or between it & the breaker box. According to the counter guys

at Southwestern Electric Supply, they are having it done one way one week

& changing their minds the next week.

A year or so down the line, they may settle down & get more reasonable or

I may come across a way, or maybe establish a connection that will

minimize the hassle & expense. Meanwhile I am going to po' boy through it

for a while. If I get shot down, I get shot down but I am going to try &

avoid getting jerked around by another utility company.

__________________

cutter

10-01-2004

posted by 7018

Now there's another reason to live where i do.I put up the pipe weather

head 200 amp box and called the power company all hooked up no

inspections. And if i would have looked its 3 phase running by my

house,Hell i must have been Blind. Oh well thats life.

10-01-2004

posted by MangleWeld

Cutter we must have done something right because they came out with boring

truck punched a new hole set a new pole, new weather head, new

transformer, meter box, disconnect, and all, put it up drove off, I said

thanks never got a bill, other than power every month. they even gave us a

new yard light on the new pole free, all we pay for in the juice it uses.

I'm beginning to think we are lucky to live where we do. Joel

10-01-2004

posted by

Cutter

posted by

Cutter

Don't worry, civilization will catch up to you some day some day & start

charging you through the nose for all those freebies you take for granted.

__________________

cutter

10-01-2004

posted by Franz

One more time, for the kids who were absent or sleeping;

Nothing in the electric utility industry is the same from company to

company, beyond they are all trying to follow the Montana Power model, and

find new ways to screw the customer.

The BEST investment you'll ever make in the process of installing or

upgrading a service is an Amprobe, or generic equivelent thereof.

Disregarding loads such as electric heat, and or air conditioning, most

houses in the US will rarely draw more than 20 amps on either side of the

service.

Meter the draw before calculating load factors, and only rarely is it

necessary to increase service size.

As far as shop/garage services -v- house services, there are some factors

that come into play that can be KILLER when the bill comes. Generally,

residential rates are 2/3 of the rate for the same KWH coming thru

commercial meters. If you live in an area where sales or use tax applys to

electricity, commercial power is generally taxed, and residential power

isn't. That tax is on top of the higher commercial rate. It's also general

practice in commercial power to install a DEMAND Meter. Demand is a

surcharge you pay the utility for just having the power available for you

to use, and it can easily double what your electric bill is.

A service installed in an attached garage, or at the other end of the

house, is a residential service. A service installed in a detached

building (shop) is a Commercial Service. This is optional with the

utility, but I have yet to meet the Baby Enron who didn't choose to meter

that building as commercial.

Even rural CoOp suppliers are now playing the Commercial power game with

farm operations.

Generally, the only way around this system of screwing the customer is a

pole service, where the meter and distribution are located on a pole, and

you put the power where you want it from there. This too is changing.

Don't expect Fred the friendly lineman or anybody from the utility to tell

you all the above, generally, even planners don't know how rate structures

run.

Also, you need to do some calculating when it comes to "basic service" or

"meter" charges. In my area, the meter charge is $23- a month, for the

meter just hanging on the wall, yours may be higher or lower.

Utilitys make a sh!tload of money from meter charges, and they don't like

giving them up. In the case of installing a large shop service, and

feeding the house load off the shop, cutting out the house meter, the

utility will generally BOMB the customer. First, they will notify the

local building department you are in violation of building code, or

electrical code, putting the govermunt on yer ***. Then, they will totally

disconnect your power, claiming there is a safety hazard. The average

house in America, without AC or a heat pump buys around 600KWH a month,

and even if you are buying it at commercial rate the profit to Baby Enron

on that 600 KWH doesn't equal the profit on the meter. Electric suppliers

are in business to make a profit.

These companys pay a number of people to think of ways you can save money,

and then file tariffs to prevent you from saving a penny.

10-02-2004

Sberry

My power company is also excellent. They dont give me any hassle, neither

do inspectors. But on the other hand I know the rules and dont need to go

around asking questions here and there and I speak the language. And when

I go to the elecrtic store I even call the parts by the right name,,, ha

10-04-2004

posted by morpheus

Where are with at with the new shop now ? why have we not seen any new

pics

__________________

Jack's Place - 4x4's, Tools, Humor, Bungi Jumping and more ....

10-04-2004

posted by 7018

Franz I don't pay a "Commercial Service" on my shop its the same as my

"house service". I guess Alabama is behind the rest of ya'

10-05-2004, 10:24 AM

posted by

Cutter

posted by

Cutter

Quote:

Originally Posted by morpheus

Where are with at with the new shop now ? why have we not seen any new

pics

Sorry Jack,

I haven't taken any pictures lately. Not very much interesting going on,

mostly just scutwork & illegal wiring. I did get a couple of lights hung

so I am not totally in the dark. Then I have found time to move a few

tools from my garage. I need to move a couple of storage cabinets work

tables from my old barn pretty soon to keep things from piling up on the

floor.

Pete & Joe, the concrete guys, started hollering about starting my new

fence last week because all of their other jobsites were under water &

still are. So Saturday I got myself out to the steelyard & bought some

used oilfield pipe for posts and they poured the curb along the east side

& set the posts. I was unable to get the sheet metal panels because Jarvis

was out of the light stone color; I located a source yesterday & will try

to pick some up today, depending on the weather. I am still trying to find

a source of rollers for a cantilever gate at a reasonable price. However,

this goofy rain-every-day weather makes me wonder if I will be able to

build the fence & gate this year anyway. One thing about it, I am sure the

roof don't leak. but the rain sure has slowed things down

__________________

cutter

10-06-2004

posted by

Cutter

posted by

Cutter

Hey, if you're thinking of building a new metal fence, or metal anything

else - I have some advice for you: do it last year before the price of

steel went nuts. I could not have chosen a worse time to undertake this

entire project although I expect it will be even higher next year. But

golly, this stuff is expensive!

Here's what I mean:

Saturday I bought twelve 7ft posts (used and rusty) oilfield tubing and

120 feet of 3 inch C-purlins for the rails - $255, including sales tax.

Yesterday I located & bought 27 6ft sheet metal panels (24 guage,

color-matched to the shop) and 96 ft of the red trim strips for a top cap

- $440.

And I finally found a source for the guide wheels for the sliding gate @

$30 each (x 4) - $120 plus freight & sales tax. These are 6 inch cast iron

with ball bearings & that price is about half of what I found on the net.

So that's about $820 so far & I still have to decide on what kind of gate

posts to buy and also buy steel for the gate frame. All this is for about

70 linear feet of fence plus a 12ft gate on the street side of my back

yard.

And, Pete, Joe & Rueben have poured the 10 inch curbing & set 11 posts;

they also threw in a walk from the driveway to the alley-side gate and a

little pad for the front entry door. And they are to haul off the old

fencing & some other trash as part of the deal - $400. Pete claimed to be

giving me a brother-in-law deal because all their other jobs are rained

out & he may have at that.

Sorry, no pictures yet. The weather has been so lousy I didn't bother. But

there is some good news - the chance for rain Wednesday is only 80%.

Damned swamp. I hope the forecast for the weekend holds true, supposed to

clear off by then.

__________________

cutter

10-06-2004, 07:13 AM

posted by rodburner

Hey Cutter what size tubing was it and how much per ft.? I am in the pipe

business and was wondering what its going for up north.

__________________

Billy

10-06-2004

posted by

Cutter

posted by

Cutter

Quote:

Originally Posted by rodburner

Hey Cutter what size tubing was it and how much per ft.? I am in the pipe

business and was wondering what its going for up north.

2 3/8ths, $1.05 per foot.

__________________

cutter

10-06-2004

posted by rodburner

Dang down here its going for 85cents a foot for used 2 3/8.

__________________

Billy

10-11-2004

posted by

Cutter

posted by

Cutter

The rains have finally tapered off for a little while, I think. Maybe I

can gradually make a dent in the fence & some other details now.

But first, along about here is where we left off when the skies opened up:

Quote:

Originally Posted by Franz

Just go to the box store and buy one or two of the $20- mercury lights and

hang them in the peak, for base lighting. out.

So I did hang a couple of the 20 dollar lights. Later on I will probably

go for the Lithonia fluorescents that linngl described in post# 305.

__________________

cutter

10-11-2004

posted by

Cutter

posted by

Cutter

Which brings me back to the task at hand - the fence. Here is a look at

where that stands - just some rusty posts sticking up out of a new

concrete curb with a temporary chainlink & hogwire arrangment to keep my

dogs out of trouble. There is a 12 foot opening across the drive just

begging for a cantilever gate for which I did finally find a source of the

necessary wheels; they are on order. Then there is about 70 feet of fence

to be built & I have scrounged together most of the materials. As you may

recall, Pete & Joe got the curb poured and the posts planted during a

break in the rain several days ago. In the meantime, I have had to go back

to work for a living.

In this view, the area between the camera and the old picket fence was not

included before; I added it to the back yard to gain back a litle bit of

the space taken up by the shop & drive. It was useless as part of a

streetside yard anyway.

__________________

cutter

10-11-2004

posted by

Cutter

posted by

Cutter

View from across the street.

__________________

cutter

10-11-2004

posted by Franz

Cutter, those are right respectible lookin lights.

Now, if you happen to see one of those fancy round stainless steel sinks,

about 12" diameter, sittin by a curb, grab it.

That sink, along with one of those cheap lights will work up into one he!!

of a portable work lamp. When you get it built, everybody who sees it will

say yer nuts, about 6 months later, the same folks will be askin to borrow

it.

10-11-2004

posted by

Cutter

posted by

Cutter

In addition to the curb & posts, I got Pete & Joe to pour a little pad for

the front door and add a walk from the drive to the back gate. I guess big

rig, et al might call this a "mandoor" pad.

__________________

cutter

10-11-2004

posted by

Cutter

posted by

Cutter

Believe it or not, they threw these in for $25 apiece additional.

Sometimes I kinda suck, huh?

The walk.

__________________

cutter

10-11-2004

posted by

Cutter

posted by

Cutter

But the real problem for the day was figuring out how to install the rails

for the fence. I am using 3 inch C-purlins & decided I want to notch them

kinda like you rollcage guys do your tubing; problem is, I am not matching

tube to tube so using a holesaw-jig kind of arrangement won't work.

But that is one reason I bought that little plasma cutter a couple of

months ago, so I set out to fab up a little fixture for it, pretty much

from nuthin', as you will see. First I sifted through a couple of boxes

out in the garage & came up with a pair of old aluminum curtain rod

brackets that I found with some other junk in a rent house storage

building last spring. Looks like they probably date back to the 60's or

'70's. Notice how they have a radius on the inside corners; that comes

into play later.

__________________

cutter

10-11-2004

posted by atucker

Quote:

Originally Posted by cutter

Pete & Joe got the curb poured and the posts planted during a break in the

rain several days ago.

I can't believe a student of Franz's Electrolytic De-rusting School

planted steel posts in that condition. Besides that, you missed a chance

at another long thread.

Allen T.

10-11-2004

posted by

Cutter

posted by

Cutter

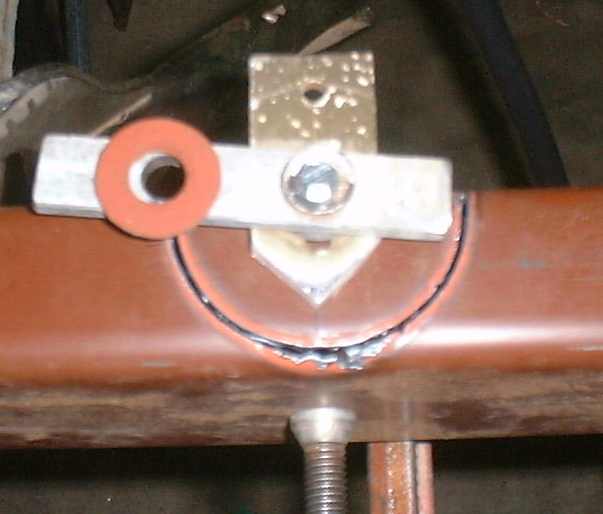

After a little shaping with a jeweler's saw and hole drilling, etc, I came

up with this little compass rigging to guide the plasma torch in a 2

3/8ths inch semicircle. I didn't have any taps available without driving

over to the old barn at night which I do not like to do unless I really

have to ( Bad neighborhood ), so I hunted until I found the right

self-tapping screw.

Here's what it looks like clamped to the C-purlin; notice that inside

radius.

__________________

cutter

10-11-2004

posted by

Cutter

posted by

Cutter

And here it is after the first cut. That red fiber washer serves as a

spacer to keep the nozzle tip from dragging against the purlin; I have

developed the notion that the mfgrs. encourage you to use the drag

technique because it burns up the consumables much faster, or so it seems

to me at this point. I sawed that point onto the aluminum so that all I

have to do is scribe a line on the purlin representing the center of the

cut & line the point up on the line to position it accurately enough for

my purposes.

__________________

cutter

10-11-2004

posted by

Cutter

posted by

Cutter

Here it is in action. Sorry about the fuzzy picture; I had trouble with

focus on all of them yesterday & I was actually running the torch with one

hand and the camera with the other on this one. Quality sucks.

__________________

cutter

10-11-2004

posted by Franz

Quote:

Originally Posted by atucker

I can't believe a student of Franz's Electrolytic De-rusting School

planted steel posts in that condition. Besides that, you missed a chance

at another long thread.

Al, you gotta remember, Cutter a/k/a Hoover is the texas & Southwest

distributor for Uncle Franz Secret Products, so he also has other rust

treatment solutions available to him. He's probably so stressed from all

these construction decisions he can't decide witch process to use.

10-11-2004

posted by

Cutter

posted by

Cutter

The I have to turn the purlin over & cut the other side before cutting the

back side because I need the cutouts left in place so long as I am

clamping the fixture to the purlin. Then it takes a little bit of grinding

because the cut runs slightly more than 180 degrees, so the back side

requires a little relief. Here is what I wound up with. Fitup won't be

perfect but its a helluva lot better than I could do freehand.

__________________

cutter

10-11-2004

posted by

Cutter

posted by

Cutter

Quote:

Originally Posted by Franz

Al, you gotta remember, Cutter a/k/a Hoover is the texas & Southwest

distributor for Uncle Franz Secret Products, so he also has other rust

treatment solutions available to him. He's probably so stressed from all

these construction decisions he can't decide witch process to use.

Indeed & besides Allen, that pipe was in my custody for about 2 days

before it got planted; I was busy with other things & didn't have time to

screw with that rust. I think I need to mop them down with Uncle Franz's

phosphoric treatment & go with that. I really need this fence built now,

and the gate, too so I may not have time to worry with the purtyness part

'til next spring.

Enough for tonight, I'll show you how this piece works on the posts later.

Heck, I may have to get to work before noon since this is Monday so I

better get my beauty rest.

__________________

cutter

10-11-2004

posted by 7018

Nice looking job cutter,are u going to drill holes in the bottom so the

water can run out?ya know i got about 400 ft of that c-purlin out in the

scrap pile. Did u think about using lite angle say 2x2x1/8?

10-11-2004

posted by

Cutter

posted by

Cutter

Quote:

Originally Posted by 7018

Nice looking job cutter,are u going to drill holes in the bottom so the

water can run out?ya know i got about 400 ft of that c-purlin out in the

scrap pile. Did u think about using lite angle say 2x2x1/8?

No, I didn't but my gut tells me that 1/8th angle would weigh more/ cost

more & also not be painted?

__________________

cutter

10-11-2004

posted by rodburner

The lights look great in the shop cutter, at least the rain has let up a

little so we can get outside and do something. At least for this week

anyway. And i bet the dogs are getting frightful being couped up in the

pen by now.

__________________

Billy

10-11-2004

posted by 7018

Quote:

Originally Posted by cutter

No, I didn't but my gut tells me that 1/8th angle would weigh more/ cost

more & also not be painted?

Otay maybe ur right i guess!!!But u do need to drill the weep holes

orrrrrrrrrr ur purlin will rust!! And thinking bout gettin some of those

lites to.

[Home] [1] [2] [3] [4] [5] [6] [7] [8] [9] [10] [11] [12]

|