|

10-11-2004

posted by Tom Zachman

The standard procedure for small tubular tower bases is to load the bottom

of the hole with some pea gravel, set the base section on the gravel and

add 4 more inches of pea gravel. Plumb the base, then top with concrete.

All water and condensation drains into the pea gravel.

10-11-2004

posted by Dman033189

Quote:

Originally Posted by Franz

Cutter, those are right respectible lookin lights.

Now, if you happen to see one of those fancy round stainless steel sinks,

about 12" diameter, sittin by a curb, grab it.

That sink, along with one of those cheap lights will work up into one he!!

of a portable work lamp. When you get it built, everybody who sees it will

say yer nuts, about 6 months later, the same folks will be askin to borrow

it.

How would you build something like that?

edit: I just happen to have a sink sitting in the back.

__________________

Don

10-11-2004

posted by Franz

Well, I guess you'll just have to wait for pictures, and that probably

ain't gonna happen tomorrow cause I got LN chauffer duty.

Go look thru the pile for some heavy duty cardtable legs, some 1¼" tubing,

and half inch pipe, 2" tubing about 3" long, enough lexan to cover the

sink, and some 10/32 x 2" screws till I do the pictures.

10-11-2004

posted by atucker

Quote:

Originally Posted by cutter

I think I need to mop them down with Uncle Franz's phosphoric treatment &

go with that. I really need this fence built now, and the gate, too so I

may not have time to worry with the purtyness part 'til next spring.

It's good those posts are outside like they are. Whatever chemical you use

won't be as much mess outside.

Things are lookin' good so far. Some of the newer light do put out a bunch

of light compared to incandescent or fluorescent.

Next time you need a fixture like that, make a template out of plywood,

masonite, MDO or even cardboard. Easier to craft than metal and also works

as a (plasma torch) standoff if you use the right thickness - or use

whatever thickness and fibre washers like you already did. For plasma

cutting, templates and Quick Grip clamps and you'd almost have an assembly

line .

Keep the story and pix coming.

Allen T.

10-16-2004

posted by

Cutter

posted by

Cutter

Quote:

Originally Posted by atucker

Next time you need a fixture like that, make a template out of plywood,

masonite, MDO or even cardboard. Easier to craft than metal and also works

as a (plasma torch) standoff if you use the right thickness - or use

whatever thickness and fibre washers like you already did. For plasma

cutting, templates and Quick Grip clamps and you'd almost have an assembly

line .

Keep the story and pix coming.

Golly Allen, I can't imagine how making a pylwood template would be

simpler, quicker or better than using a useless old curtain rod bracket, 2

inches of 1/8th x 1/2 inch strap & 1 screw? Nearly all the time was

invested in finding the old bracket & the right self-tapping screw.

About the only significant development for this entire week began as I was

trying to sleep late Monday morning and the phone yanked me out of bed; I

could hear my answering machine yapping & when it stopped, my cell phone

started ringing so I shoved myself up & toddled down the hall to find out

what was so blasted important as to pry me up at the crack of 8. It was my

gutter guy; now that the rain has finally ceased, he wanted to come

install the gutters on the shop. So he did & I am glad for that; water

running off of the north side onto the back porch cover and then off into

the narrow gap between the structures had been keeping my porch soaked and

mud was constantly washing up onto the concrete. Runoff also splattered

onto the shop door so I had to keep it shut all the time or a surprising

amount of rain got into the building. Of course, I expect the gutters to

be a rain killer anyway; now that I spent money on them, we won't see a

storm cloud for a year or so.

As far as the fence goes, I had just enough work this week to keep me away

from the house every day 'til nearly dark or until my tank was about empty

anyway - that being the tank where I keep energy & motivation. It doesn't

hold much any more.

I finally got out back late Friday afternoon & found that some

yellowjackets wanted to stake a claim to the shop. At first there were 3

of them buzzing around & seemed to be fascinated by the mercury vapor

lights. They were bashing themselves against the bulbs and getting madder

by the minute so pretty soon they were swooping & looping and generally

becoming a big nuisance so I poked around the garage & came up with a can

of Wasp & Hornet spray to gentle them down with. Well, an hour & a half

later, I had a floor littered with the damned things & the whole shop

stunk so bad I didn't care to hang out in there very long. I didn't

realize that wasp spray smelled so bad when you use it indoors.

Did I mention that I have a cold? Well, I do, felt lousy on Thursday & got

up sick Friday morning. Went back to bed & slept til 2. Maybe a long

leisurely weekend will help some.

Oh yeah, I finally got around to taking some pictures of my Atlas

babylathe that I mentioned a couple of weeks ago. Out of deference to Red

Caddy Paul's proposed 'who has the biggest thread' challenge, I will post

them in a new separate thread so as not to pad the hit count on this one.

__________________

cutter

10-16-2004

posted by atucker

Quote:

Originally Posted by cutter

Golly Allen, I can't imagine how making a pylwood template would be

simpler, quicker or better than using a useless old curtain rod bracket, 2

inches of 1/8th x 1/2 inch strap & 1 screw? Nearly all the time was

invested in finding the old bracket & the right self-tapping screw.

Not to be argumentative, BUT. Take an appropriately sized hole saw (or

sabre/jig saw) to a scrap of plywood of the correct thickness (or use

fibre washers too), cut the thing in half (assuming you used a hole saw),

clamp it to the c-purlin and away you go. Of course, you probably have the

same problem I do - doing this stuff is not the problem, finding the stuff

is the problem .

Allen T.

10-16-2004

posted by

Cutter

posted by

Cutter

Oh sure, I have done the holesaw template bit lots of times, especially

boring out old doors on site for 2 1/8th inch locksets. But then I

wouldn't get to play with my plasma cutter? What can you possibly be

thinking????

And the little compass template is easily adaptable to any size hole for

future use. On top of every other reason, all my woodworking tools are

still locked up in the old barn 5 miles away. I don't want to jam all that

stuff in here just yet so I am getting by on minimal tools for this fence

project & some other things yet to be done.

__________________

cutter

12-25-2004

posted by

Cutter

posted by

Cutter

thimble & stovepipe

Dang, it has been so long since I've looked in on my shop thread, I had

nearly lost track of it.

But in case ya'll hadn't noticed, there's been a bit of a cold snap lately

which has brought to my attention the fact that my shop building is still

not heated other than by a kerosene fired Redi-heater & who can afford

kerosene anymore?

But to the point: What's the best way to run a thimble & stovepipe through

sheetmetal & seal it, remembering that I also have vinyl-clad rolled

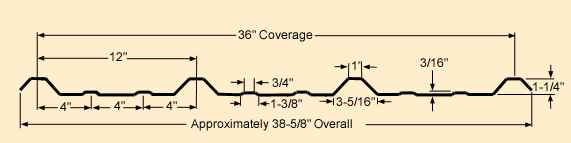

insulation to protect as well? My only experience with this involves

compostion roofing which is a different cat altogether as far as I am

concerned. I have attached a profile of the R panel sheet metal.

I have a Vogelzang woodstove to install & I have drug my feet about doing

it because I hate screwing up the integrity of the sheet iron roof; I do

not want to create a leak.

Tia,

cutter

__________________

cutter

12-25-2004

posted by moe1942

Cutter,

I went through the wall with my pipe. I was afraid that I would cause a

never ending leak situation if I went through the roof.

Use double wall pipe where you transition through the roof or wall. There

is pipe rated for zero clearance which will be necesary for use in the

insulation.. Then use a thimble with sealant for a tight seal.

As for cutting the hole, aircraft sheetmetal shears or better yet an air

nibbler works well.

Hope I understood the question and didn't cover things you already knew.

Hope this helps.

Merry Christmas..

Moe

__________________

If you can read this thank a teacher, and it's in English so thank a Vet..

"If we ever forget that we're one nation under God, then we will

be a nation gone under". ~Ronald Reagan

12-25-2004

posted by Franz

Take it thru the wall Cutter. You'll choke when you see the price of the

collar for the roof, and every damn one of them I ever saw leaked.

12-25-2004

posted by Scott V

I would use double wall pipe like Tom said. Also for my Metal roof (snap

loc style) they make a hi temp silicone pipe flange. It will form over the

smaller ridges and just seal to the roof with screws, vulkem sealer. It's

the right way to do it!!!

12-25-2004

posted by Bolt

I now have 10 pipes running through the metal and insulated roof of our

barn, some of them thanks to Franz. None of them leaked, and all the ones

I installed I used one of the flexible, rubber and thin metal roof sealing

thingy's and a lot of silicone and some screws. It forms over the ridges,

and seals good. The bigger ones, (10 inchers) are set into the middle of a

rib, so that the water does not dam up behind it and possibly create a

leak, this way it can still go around both sides of it. I buy the boots at

McCoys.

12-26-2004

posted by

Cutter

posted by

Cutter

Quote:

Originally Posted by moe1942

Cutter,

I went through the wall with my pipe. I was afraid that I would cause a

never ending leak situation if I went through the roof.

Use double wall pipe where you transition through the roof or wall. There

is pipe rated for zero clearance which will be necesary for use in the

insulation.. Then use a thimble with sealant for a tight seal.

Quote:

Originally Posted by Franz

Take it thru the wall Cutter. You'll choke when you see the price of the

collar for the roof, and every damn one of them I ever saw leaked.

Yeah guys, I like the idea of not making a hole in the roof but I would

want it to exit pretty high off the floor on the north (10 foot) side &

that doesn't leave much of anything to anchor the outside part to, or to

support the weight & that insulated, twist-lock pipe is heavy. I ran the

pipe for my house stove though the roof with no problem; had to buy a $125

kit to get the ceiling collar, thimble & roof jack. But it worked. Since I

don't have a ceiling in the shop I should only need a roof collar/jack or

something to make it work - IF it will seal effectively.

I have a source of both plain & insulated pipe. I'm just hunting the stuff

to make the hole work.

__________________

cutter

12-26-2004

posted by

Cutter

posted by

Cutter

Quote:

Originally Posted by Scott V

I would use double wall pipe like Tom said. Also for my Metal roof (snap

loc style) they make a hi temp silicone pipe flange. It will form over the

smaller ridges and just seal to the roof with screws, vulkem sealer. It's

the right way to do it!!!

Quote:

Originally Posted by Bolt

I now have 10 pipes running through the metal and insulated roof of our

barn, some of them thanks to Franz. None of them leaked, and all the ones

I installed I used one of the flexible, rubber and thin metal roof sealing

thingy's and a lot of silicone and some screws. It forms over the ridges,

and seals good. The bigger ones, (10 inchers) are set into the middle of a

rib, so that the water does not dam up behind it and possibly create a

leak, this way it can still go around both sides of it. I buy the boots at

McCoys.

Okay Bolt & Scott,

That's the part I'm hunting - the roof seal. Guess what - Home Depot &

Lowe's ran our McCoy's stores out of town when they moved in several years

ago. Guess where the nearest one is now? Uh huh - Plainview.

So Bolt, can you supply a picture, brand name & model number or something

so I can call that store down the street from you & talk to them about it

before I come running up there?

__________________

cutter

12-26-2004

posted by Franz

Cutter, did you try the manufacturer of the building you bought for a roof

flange?

The only place you need double wall pipe is going thru the roof itself,

the distance from a wood stove to the roof is radiational heating and very

productive.

12-26-2004

posted by

Cutter

posted by

Cutter

Quote:

Originally Posted by Franz

Cutter, did you try the manufacturer of the building you bought for a roof

flange?

No. It might be worth a phone call to Mueller to ask but I will be very

surprised if they have anything. However, since I put this thread in the

Equipment, Suppliers and OEM's forum so I could plug the company once in a

while, I'm glad you presented me with the opportunity.

Quote:

Originally Posted by Franz

The only place you need double wall pipe is going thru the roof itself,

the distance from a wood stove to the roof is radiational heating and very

productive.

And yes, that's the reason I want maximum exposed plain pipe inside the

building. I already have enough insulated 6 inch pipe & may be able to

salvage enough black pipe for the rest of this season from my old

installation. But I suspect it has probably rusted pretty badly by now. I

also considered slapping a barrel diffuser together but I think the old

legless Vogelzang will be sufficient.

__________________

cutter

12-27-2004

posted by Bolt

Sure cutter, I will stop in there maybe tommorow, probly Tuesday and get

the info you need on it. You need something in the 6 inch range, right?

12-27-2004

posted by

Cutter

posted by

Cutter

Quote:

Originally Posted by Bolt

Sure cutter, I will stop in there maybe tommorow, probly Tuesday and get

the info you need on it. You need something in the 6 inch range, right?

6 inch (internal) insulated, Bolt. I'd have to climb up on the roof right

now to measure the O.D. of one. I thought maybe you'd have an invoice or

receipt from where you'd bought them before, didn't mean to put you out to

a special trip. But I do appreciate it. Maybe we can go to lunch on me.

__________________

cutter

12-27-2004

posted by Bolt

Well the most recent invoice I've got is for a 3.5 inch, and all the rest

of the reciepts are filled away in some system I try not to understand.

It's no biggy for me to stop in there, I will find something else to spend

money on at that place anyways. How soon are you looking to need one? I'm

usually in Lubbock every week, but not this time of year, during christmas

and all. Just let me know, I'm sure I need to go there again sometime

soon.

12-27-2004

posted by

Cutter

posted by

Cutter

Aw Bolt, don't be so accomodating that you screw up my chance to run up

there & see you. All I really wanted was for you to make sure they have it

in stock before I drive up there. I could call them but you know how it

goes when you try asking a clerk if they have something when you don't

know what they call it?

Seriously, I can come get it nearly any day this week. I also need to put

the squeeze on my son in law & find out where he stored my other left-over

pipe & such so I can figure out what else I am going to need to buy.

__________________

cutter

12-27-2004

posted by Scott V

These are the ones I use. The flasher round ones.

Pipe Boot Express

12-27-2004

posted by madam X

Quote:

Originally Posted by cutter

Aw Bolt, don't be so accommodating that you screw up my chance to run up

there & see you.

If there's a meeting, we need to see pictures! It's in the SFT bylaws.

__________________

madam X - Site Empress for Life

Director of Policy, Inane Matters (by appointment)

Sic gorgiamus allos subjectatos nunc

Now go kill something for me

12-27-2004

posted by Franz

Bolt, be real careful if Cutter shows up around your place. He's an old

cow milker, and might revert to his 1st childhood ways. Of course, you

coluld always put him on as a night shift milker. Might take a bit to

transition him to modern bulk methods as opposed to 20 gal cans though.

12-28-2004

posted by

Cutter

posted by

Cutter

Quote:

Originally Posted by Scott V

These are the ones I use. The flasher round ones.

http://www.pipebootexpress.com/

Those certainly look & sound like the solution, Scott. Thanks.

__________________

cutter

12-28-2004

posted by

Cutter

posted by

Cutter

Hey Bolt!

Bolt, did you get the private message I sent a couple of days ago?

__________________

cutter

12-28-2004

posted by Bolt

Yes, I got your email now, and I sent one back to you with the info you

need.

01-08-2005

posted by

Cutter

posted by

Cutter

Quote:

Originally Posted by Scott V

These are the ones I use. The flasher round ones.

http://www.pipebootexpress.com/

Scott, these guys are super.

Bolt, McCoy's only carries the smaller diameter boot, up to 6 inches OD, I

think; I called the store last week & the nice lady looked for me. I think

I failed to make myself clear to you in that I need to use a 6 in I.D.

insulated stovepipe; the wall thickness is about 2 inches, making a total

outside diameter of 10 inches.

So I called the PipeBoot folks last Monday, talked to Tim & explained what

I was doing. He confirmed my choice of the 7 - 13 inch round Flasher (#8

Flasher - Gray-EPDM item # MBAFG0335). So I went back to the site &

ordered it for $33.02 plus UPS ground ($9.75) Next morning I had a

shipping notice with a tracking number. So I got busy with day to day

work/crap & pretty much forgot about it.

Thursday I came home early with a can of kerosene ($2.55 a gallon for

pete's sake!) for my temporary (I hope) readyheater & stopped at the shop

drive to unload it so I wouldn't have to wag it through the house. After

the usual welcome home formalities with my dogs, I went out back, straight

through the shop & retrieved the kerosene, waving to the driver of a brown

truck in the process. Lit my heater, spent a little while on this board

while the building warmed up & then worked on a drill press & other things

off & on until bedtime.

Friday morning, I remembered to check UPS tracking before leaving for

work. The website said "Delivered 01/06/05. 5:31 pm." Oh really? Then I

opened my front door & there she sat, been there all night. That's when I

remembered seeing the UPS truck turn the corner the night before. Duh!

The point is, that was a 2 or 3 day turnaround for an order from Sanford,

Fla to Lubbock, Tx & in my book, that's super sevice.

Someday I will maybe be able to round up the last critical part - the

"ceiling canopy" which supports the weight & sideways stress of the

insulated pipe and also serves as the adapter between the indoor plain

black pipe & the insulated. And it protects the roof insulation as well.

For the one in my house, I had to buy a $148 kit from Lowe's & I intend to

find some way around that this time.

Now I have to somehow squeeze that young feller who is soon to be my

former (so I hear) son in law to get one 4 ft piece of unused pipe back

from him, which supposedly is in his rental storage unit.

__________________

cutter

01-13-2005

Bolt

That's right, cutter, the one at McCoy's was a #5 masterflash, and I think

on their website it says that it it will take 7 inch od pipe or something.

I was not aware that your pipe was 10 inch OD, didn't know you were using

real pipe, i figered maybe the thin double walled stuff I see used on

water heaters and stuff like that.

Now to be fair, you did never give me an OD of your 6 inch double wall,

did you Just messing with you.

Aren't you supposed to be keeping the heat inside, not letting it go out

the chimney?

Good to see that it worked out for you with the pipeboot people. I am

usually pleased with UPS's service, it is Fed Ex that really chaps my ***.

01-13-2005

posted by Scott V

Yes,

they have a pretty good layout on the website. You can find stuff. It

looked like good prices too.

01-16-2005

posted by storts

Hello Everyone

Hello to everyone, Cutter, ive been reading, and had to register at page

18, Everyone seems so pleasent and like to have some fun also ,,,Im

putting up mine in about 2 months, im from Killingworth,Ct. and i sold my

commerical building ,in Meriden, ct. that ive had my shop in for 27 years,

It was a old brewery, and was built in 1883,24" thick walls, etc, but

needed i cant guess in $ what it would need for repairs, so found a buyer

,and i have 10.5 acres, and every other person in town(population4100) has

there own building, shop, barn,etc and it 100% legal, ive been reading for

3 hrs, and you are doing a great job, best of luck and hellow everybody,

going back to finish reading, hope everything turned out ok, I like the

idea of just walking to work,sure wish i could get 3 phase , they dont

even have it on the street and nice meeting everybody, Jack Connors

01-16-2005

posted by Wyoming

Storts, Worked a job down in Kentucky years ago building a dam on the

Martin's Fork of the Cumberland. Construction company was Lane

Construction out of Meridan, CT. Are they still around?

01-16-2005

posted by

Cutter

posted by

Cutter

Welcome to our playground, storts. I do believe you have found yourself

some kindred spirits here & I am delighted that the shop thread rang your

bell. Someday, I hope to have something halfway significant to add to it.

We have kids, women, dogs, hobbyists, wannabe's, getting-theres, some of

the best professional machinests, weldors, fabbers, farmers &

electricians, mechanics & teachers you can ever hope so find in this small

a group. We even have own own chemist, an optical consultant & one

mortician. Then we also have beenthere/donethats that know something about

everything or at least where to find out. This is a wonderful resource and

some of the nicest people you'll ever meet - at least until the next

national election.

Make yourself at home. Don't hesitate to speak up, we love questions,

answers & pictures of just about anything.

__________________

cutter

01-16-2005

posted by storts

The Throne

Quote:

Originally Posted by cutter

Here is where my afternoon went; we got the door up & the inside plumbing

done. We still have to install the lift spring tomorrow & do some

adjusting but at least the weather is finally held at bay which might be

handy since the forecast is 30 - 40 % chance of rain for the next 3 or 4

days. And the water is on, potty works. The wind has been blowing all day

& the floor is pretty well covered with grit - situation normal.

Sorry, im New , Butt I have tears coming out of my eyes laughing, Its like

Ive known Cutter for years, This is better than any novel you could read,

had to go back to see the location of your walkin door, Cutter sittin on

the throne, reading the paper, and a cust. comes in, He looks up, and

says, Can i help you Sister ann, Where is Father Byrun?,,,Could no resist

,Jack

01-16-2005

posted by storts

Wish you were closer,

Quote:

Originally Posted by cutter

Well fellers,

This not a public building & this is not a public restroom so I am kinda

of thinking of letting this little john be a part of the profit, or what

you might call a "pay as you go". If you just gotta have privacy, privacy

is available - for a price. There will be a curtain you can draw for a

buck. But before you do that you will want to read the full menu of

options; if you want paper, for instance, its 10 cents a square or 25

cents a foot. Handi-wipes (for your hands) are 50 cents, Purell is a

dollar a squirt and the big money maker - Preparation H - is 2 dollars an

inch (bring your own nozzle unless you want to rent one. Don't ask. ). And

no, there ain't no separate accommodations for ladies; this thing has

already cost me a bundle.

Cutter , When i moved from my building i sold, Im definatly Pres. of rat

pack Collectors, and i have a ton of 400, 20 gauge SS, Thant would make

for a nice covering over sheet rock, The shipping would be crazy,,PS Best

book ive read in years, Jack

01-16-2005

posted by storts

Vent

Quote:

Originally Posted by cutter

Here is how it all fits together. There will be a laundry-type sink on the

outside of the partition. That puts the sink in the work area, not in the

commode area. Initially it will be cold water only; later I can add a

small electric heater, 20 gallons or so.

Cutter, ive always played with plumbing, and built my own house, Timber

frame, post and beam, not a nail in the house, so in ct we call it a pro

vent, kinda looks like the same,so when you put a sink in a island,

toughest house i ever wired or plumbed, all stess skin panels,lots of

planing !!!!! and a couple of 2" pvc pipes to second floor in case you

need to run a wire or some thing later, and vidio taped everything , Just

in case, I must be getting old(49) but remember the song? here i sit

broken hearted, payed a dime and only.....ed you know the end, Jack

01-16-2005

posted by storts

Lane Construction,

Quote:

Originally Posted by Wyoming

Storts, Worked a job down in Kentucky years ago building a dam on the

Martin's Fork of the Cumberland. Construction company was Lane

Construction out of Meridan, CT. Are they still around?

Sure are , and a very good cust of mine, did you ever do any work for C.N.

Flagg Co?Jack,There from meriden, also and used to do alot of work with

Lane, Pete Flagg sold the buisness years ago, and they were a powerhouse

of a mechanical Contractor, they did millstone, Indian point, half the

nuke plants around the USA. Small world , Just would not want to paint it,

Nice meeting you, what a great book Cutter rote!!!!!Jack

01-16-2005

posted by storts

Hi Cutter And thank you,

Quote:

Originally Posted by Wyoming

Storts, Worked a job down in Kentucky years ago building a dam on the

Martin's Fork of the Cumberland. Construction company was Lane

Construction out of Meridan, CT. Are they still around?

Sorry Cutter i dont know how to respond to you message back to me, well,

Best seller, if you had to sell it, and im far from bashful, Been callled

a half bubble out of plum, but proffecianal when you have to, also worst

speller going, Sorry, But thanks for the responce, took 4 hrs to read, my

wife was wondering why i was screaming laughing my a$$ off,,think i might

of even ,,,,wellll you know, Thanks again, and you will deffently will be

hearing me chirp in, Thanks again for that great story, when istart mine ,

i know i cant top yours, still need to learn on how to upload pics, You

made my Sunday!!!!!!, Jack Connors

01-16-2005

posted by Wyoming

Storts,

No on the C.N.Flagg company. I never did get near CT while working for

Lane Const. Just drove out to KY after finishing a dam in OK to check out

the jobsite and got a job with Lane while talking to the people on site.

Enjoyed working for Lane Const...good quality people willing to spend the

money needed to ensure a good, healthy, quick project. First and only time

I've ever had the opportunity to use a diesel powered moving arbor table

saw.

Dig around and find Cutter's vise thread...its even better than the shop.

01-16-2005

posted by madam X

Quote:

Originally Posted by cutter

This is a wonderful resource and some of the nicest people you'll ever

meet - at least until the next national election.

Was there an election? <ducking>

Hi storts!

__________________

madam X - Site Empress for Life

Director of Policy, Inane Matters (by appointment)

Sic gorgiamus allos subjectatos nunc

Now go kill something for me

01-16-2005

posted by

Cutter

posted by

Cutter

Quote:

Originally Posted by Wyoming

Dig around and find Cutter's vise thread...its even better than the shop.

Wy, you're not all of a sudden pimping for wanking web, are you?

(there is no vise thread here.)

__________________

cutter

[Home] [1] [2] [3] [4] [5] [6] [7] [8] [9] [10] [11] [12]

|